Manufacturing and Repair of Turned and Cast Products

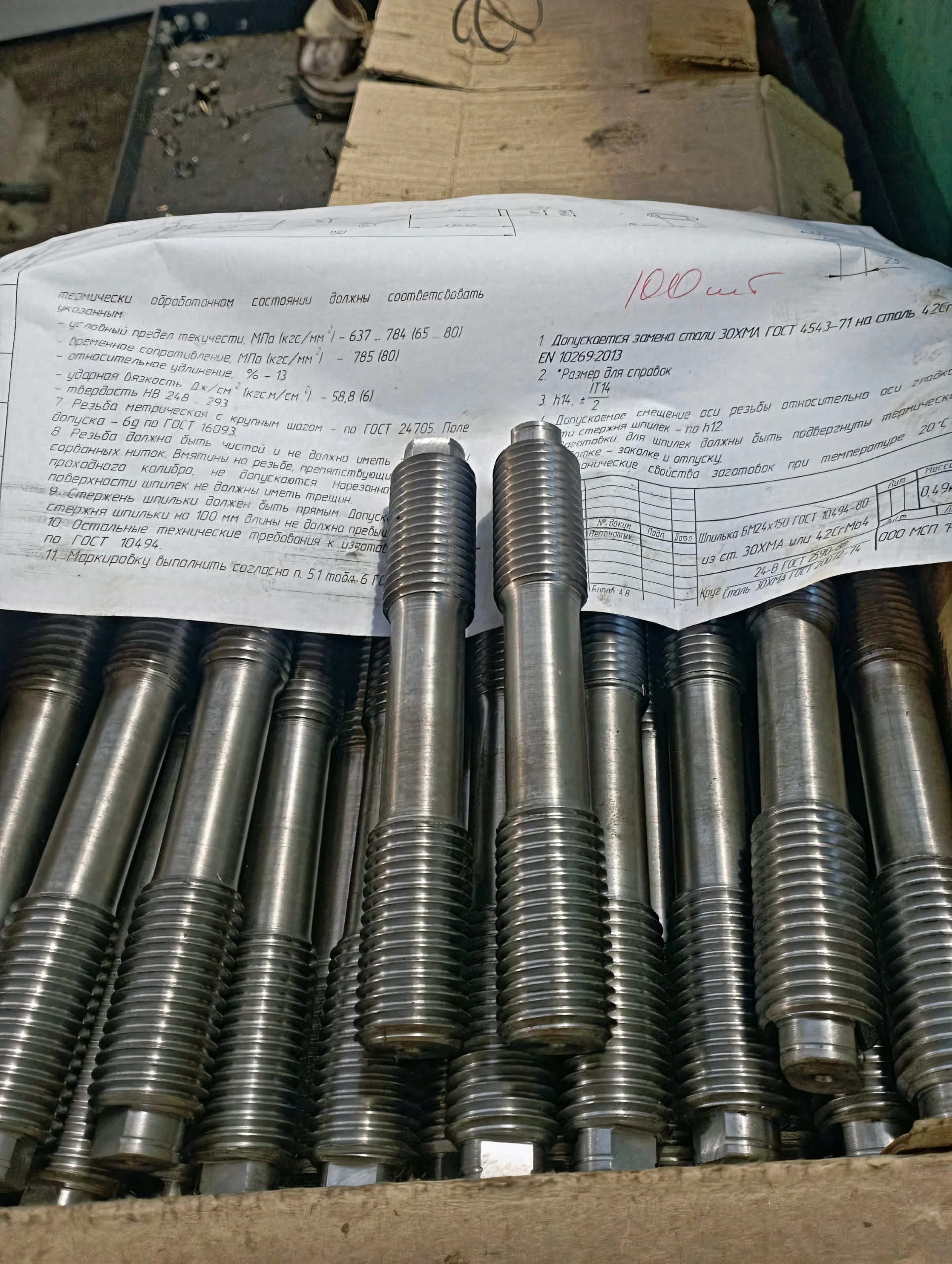

Mechanical processing for the production of various parts: shafts, gears, bushings, studs, bolts, nuts, flanges, nozzles, couplings, pulleys, disks, and other components.

We ensure high manufacturing precision by utilizing modern equipment and technologies, enabling us to handle both custom orders and serial production of parts for various industries.

List of works on mechanical processing of parts:

01

Turning and threading works (∅2÷∅1200 L=6000mm)

02

Milling work: working movements longitudinal 1000 mm, transverse 300 mm, vertical 370 mm, parts weighing up to 500 kg

03

Boring work: maximum boring diameter up to 1400 mm

04

Grinding works (circular grinding ∅5÷∅450 L-2500, surface grinding 400÷2000)

05

Gear milling work: up to ∅ 500 mm, module up to 10 (cutting spur and helical gears; worm wheels; external involute-spline joints)

06

Planing work: overall dimensions up to 900x2500 mm

07

Chipping work: maximum slider travel 500 mm

08

Drilling work: drilling diameter up to 50 mm and length up to 350 mm

09

Potting with lead-tin alloys (application of galvanic electrolytic anti-friction lead-tin coatings with a thickness of 1-200 microns)

10

Forging and pressing works: workpieces weighing up to 30 kg, furnace temperature up to 1300 °C, weight of the falling part of the hammer up to 750 kg

11

Thermal work: heating furnace temperature up to 900 °C, dimensions 500x700x1700. Microwave work up to Ø250mm, height 20mm or Ø100mm x 80mm

12

Flame coating of lead-tin alloys (sliding bearings, pistons, thrust blocks and bushings, etc.)

Photos and video materials

Inspection, repair and adjustment of shut-off valves

- Inspection and repair of valves, taps, gate valves – DN 25–400, PN 0.4–32 MPa. Optionally, gate valves DN 450–1200.

- Inspection and repair of gate valves and back valves DN 50–1000.

- Inspection, repair and adjustment of shut-off and control valves with pneumatic and electric actuators.

- Inspection, repair and calibration of safety valves DN 6–250, PN 0.3–20 MPa.

We apply the following equipment:

- turning-screw-cutting machines: 1A670 (DIP1000), 166 (DIP600), 1M63 (DIP300), 1A625, 16K20M and others;

- turning-carousel: KCF320(RAFAMET), 1512, 1525, 1M557 and others;

- horizontal-boring: 2A622, 2L614, 2652 and others;

- coordinate-boring: 2450, 2E450AF30 and others;

- milling machines: F400, FSS-315, FSS-400, 6P13, BF20 Vario 20 Optimum and others;

- grinding machines: centerless grinding 3184, cylindrical grinding 3172, 3A164

- surface grinding 3D725;

- Gear-producing machines: gear milling 5K32A, gear-shaping 526, gear-generating 5B115, and others.

- Band sawing machines: SG5018, Opti SAW S275N, BMSO 350 and other.

- Resistant furnace: CHO-3x6x2/10-I2, CHO-9.14.7/10I1, and others.

- Induction device IZCH-100/8.

- Stand for hydraulic test of tube fitting SI-11, SI-21.

- Stand for relief valve testing and setting DN10-300, Pmax = 45 MPA (PKBA SI-14M).

- Arc surfacing facility of detail sealing surfaces.

Have Questions?

Calculate the cost of manufacturing parts

Our specialists will contact you shortly after receiving your request to discuss the details and clarify all questions for an accurate cost estimate.

Thank you!

Your application has been received

Our specialists will contact you

as soon as possible to discuss the details

and clarify all questions for an accurate calculation.